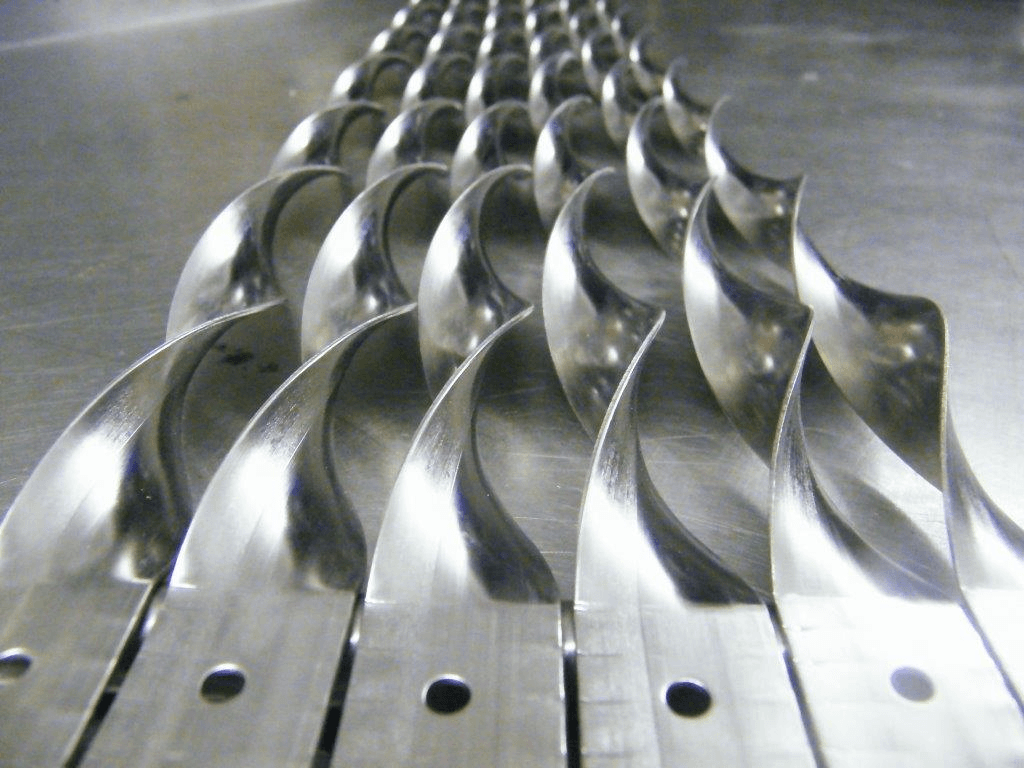

Twisted Tapes Heat Exchangers:

Twisted tapes heat exchangers are an additional type of tabulator that Coil Gavin manufactures. Twisted tapes can also be installed as retrofits or for new designs of heat exchangers. Twisted tape heat exchangers are a historically well-known heat transfer enhancement product, and as such a variety of heat transfer and pressure drop correlations are available in the public domain. For that reason Coil Gavin does not offer a thermal performance guarantee for this enhancement device.

Image:

process:

The Twisted tapes heat exchangers are heat transfer and pressure drop characteristics can be varied by changing the twist pitch of the device. Typical twist pitch ratios possible to manufacture (360o twist pitch / tape width) are between 6 and 18. The width of the tape is specified to allow a small gap between the tape and the tube wall. Big clearances between tube wall and twisted tapes can cause bypass flow and thermal underperformance. To secure the tapes a key wire connecting the twisted tapes can be passed through the holes provided at both ends of the tape (see picture). If required Coil Gavin can provide supervision service for installation.

Materials:

- Carbon steel

- Aluminium

- Stainless Steel 304, 316

- Copper

- Stainless steel types.

Features:

- High heat exchangers speed, high temperature resistance (400°C) and high pressure resistance(2.5MPa); High efficiency and energy conservation: The heat transfer coefficient reaches 3000-4000W/m2.°C in the transfer from steam to water and 2000-3500 W/m2.°C in the transfer from water to water.

2.The pipes of heat transfer are stainless steel, so they have a long service life which is over twenty years.

3.High water storage capacity . - There are hardly dead water places in the heat exchanger, the availability of volume is high, water waste is small, and water supply is safe and stable. Designed flexibly, complete specifications, practical and fund scan be saved. With the large water storage, the little cold water places in the heat exchangers, the high volume’s availability, less water head loss; it has the safe and stable water supply effect.

5. Flexible Design, complete specifications, practical and narrow target and saving the cost well. The heat exchanger is able to inspect water temperature continuously and automatically, then control the temperature accurately by instructing control valves to regulate the hot mediator’s flow rate in the coil pipes. - The temperature of outlet water can remain in the scope of 2°C of the set point under the condition of load fluctuation. Low maintenance costs, easy to operate , long period of cleaning fouling, and easy cleaning.

Advantages:

- High heating efficiency for pool heating, big flow volume, compactable, easy installation and durable.

- Material: All stainless steel 316L or titanium

- Max design temperature:208°C

- Max. working pressure:1.3Mpa

- provides higher transmission performance

- Uniform heat transfer

- More economic

- For fast high temperature heating and fast low temperature cooling

Applications:

- Preheat

- CRU Combined Feed

- Construction machinery,

- Compressor,

- Air separation,

- Chemistry industry,