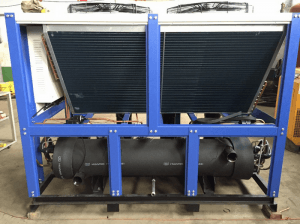

Air Cooled Scroll Chiller is suitable for small-medium scale industrial process cooling, such as side-by-side cooling for injection molding machine and other production process which needs cooling.

Standard Futures

- Cooling temperature range: 5℃ to 35℃.

- R407c environment friendly refrigerant.

- Stainless steel insulated water tank.

- Danfoss scroll type compressor.

- Schneider electric components.

- Reliable control panel with full English menu, easy for operation.

- High/low pressure protection for gas circuit.

- High/low temperature limit for cold water.

- Water level switch/flow switch, to remind the Shortage of water.

- Overload protection for all electric motors.

- Adequate aluminum fin type condenser with large

- air volume fan, with no need of cooling tower.

- Regular pressure pump as standard configuration.

Optional Features

- In Air Cooled Scroll Chiller High pressure pump for different application.

- All stainless steel water way, to satisfy high quality water cooling.

- Shell and tube/plate type evaporator.

- Tank level indicator, to monitor the water level of the tank.

- Water pressure guage, to check the water supply pressure.

- Refrigerant solenoid valve, to further protect the compressor when stop.

- Sight glass for refrigerant, to monitor the running condition of refrigerant circuit.

How Does a Refrigeration Circuit Work

The refrigerant goes through the compressor, compressed into high temperature high pressure gas, then passes through the condenser and turns to liquid with its heat removed by condenser. After That, the liquid refrigerant enters the expansion valve, and becomes low temperature low pressure

gas after expands, in this way it can go to the evaporator and absorb the heat of cooling medium(water, oil, etc.), then turns back into the compressor. The circulation process repeats until the required chilled water temperature is reached. Compressor, condenser, expansion valve and evaporator are four indispensable parts in a chiller unit.

Other Important Components

- Pressure Switch, alarms when refrigerant pressure is not in a safety range.

- Level Switch/Flow Switch, alarms when the water in the tank(or the pipe) is not adequate.

- Reservoir, avoids refrigerant that does not liquefy from going to the expansion valve, so to make

- sure the refrigeration performance.

- Manual Valve, cuts the refrigerant circuit in case of maintenance.

- Dry Filter, prevents moisture or impurity from running in the system.

- Low/high Water Temperature Limit, alarms when the water temperature is not within the safety working range, protects the cooling object and the chiller unit itself.!