Aero Dynamic Cooling Towers:

Aero dynamic cooling towers on the local low-level concentration of pollutants emitted from nearby stacks were investigated in a wind tunnel. These investigations were limited to neutral atmospheric conditions. The problem results from the large capacity of modern power plants which are equipped with Aero dynamic cooling towers. For an effective natural vertical draught, Aero dynamic cooling towers types of cooling tower are of a height of at least 160 m. The flow field within the atmospheric boundary layer generated by the effective surface roughness of the surrounding terrain is heavily disturbed by aerodynamic interference in the vicinity of the cooling towers. Therefore, diffusion of effluents from stacks located in the wake of such cooling towers cannot be calculated by use of the Gaussian plume model of dispersion.

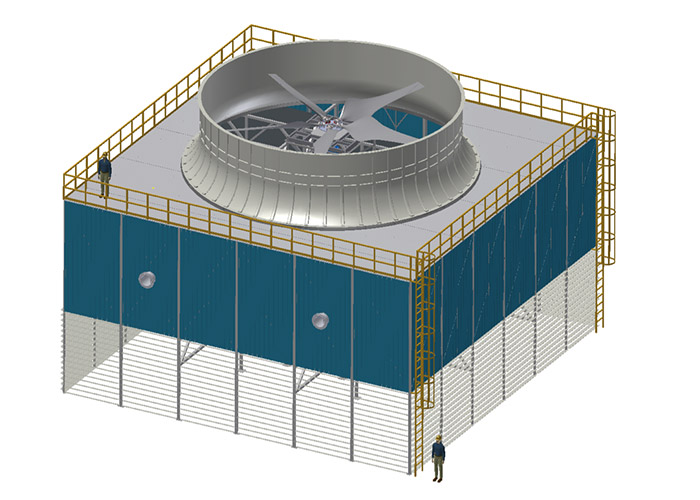

Image:

Process:

Aerodynamic cooling tower has an evaporating tower, air-guide baffles with a rough surface located at the inlet ports, vortex generators are admitted to it, the vortex generators are made in the form of an impeller with a generator and positioned in the area of the tower inlet ports, the top of the tower is covered by a structure of thin vertical strips reducing the horizontal component of the wind flow penetrating into the tower. Information on the local field of concentration was obtained from experiments in a wind tunnel. The experiments showed that the ground-level concentrations increased heavily in the vicinity of the cooling towers, compared with those of an isolated stack of the same height and shape.

Design:

Design of Aero dynamic cooling towers inertial drift eliminators of wet cooling towers are studied para metrically for their blade shapes, orientation with respect to gravity, solidity ratios, blade sizes, approaching air speed, and drift spectrum. The fundamental behavior of drift eliminators is revealed by non dimensional parameters. A method for the optimum design of an eliminator considering minimum cost versus performance is developed. This methodology can be integrated into the optimum design of the whole Aero dynamic cooling towers system.

Advantages:

- With our expertise in the axial fan blades design SCPL uses the most efficient aerodynamic profile for the blades designed we accept the challenge to prove power saving not only over metallic cooling tower fans but also against other FRP cooling tower fans.

- Only SCPL cooling tower fan blades have the aerodynamic profile over its full blade length compared to other manufacturers providing conventional cooling tower fan having approximately 30% blank portion in the blade which does not present aerodynamic profile.

- SCPL aerodynamic hub is the best solution for reduction of air turbulence near the neck of the cooling tower fan blade and to reduce the mechanical hub dimension as well.

Applications:

- Force draft cooling tower fans.

- Induced draft crosses flow cooling tower fans.

- Induced draft counter flow cooling tower fans.

- FRP Cooling towers fans

- Timber Cooling towers fans, and

- Concrete cooling tower fans.