Marine Heat Exchangers

Overview:

This high quality of marine heat exchanger has copper-nickel tubes and end caps to resist corrosion and marine growth. Only the closed circulation coolant contacts the aluminum alloy body. This is a great unit to replace your old, rusted, leaking or clogged heat exchanger or for use in a new installation. A marine heat exchanger consists of a set of corrugated metal plates, rubber gaskets and frame.

Principles of Marine heat exchanger technology designed to combat one common problem in the process industry: Fouling. Process Plants spend a significant fraction of their budget due to fouling which lead to blockages. Blockages occur in multi-channel heat exchangers such as the plate heat exchanger and the shell and tube heat exchanger. The phenomenon is preferential flow: This occurs when you have a fouling stream that begins to block some of the channels in a heat exchanger which will let most of the flow go through the unblocked channels. This will mean less heat transfer area left. Spiral Heat Exchangers are designed usually with one channel (at most two), which means that the preferential flow phenomenon is literally eliminated and therefore blockages almost non-existent. Products used for marine heat exchangers Cupro-nickel marine condensers, 070:30 Cupro nickel heat exchangers, Twisted tube heat exchangers, 90:10 Cupro-nickel marine condensers, 70:30 Cupro-nickel marine condensers.

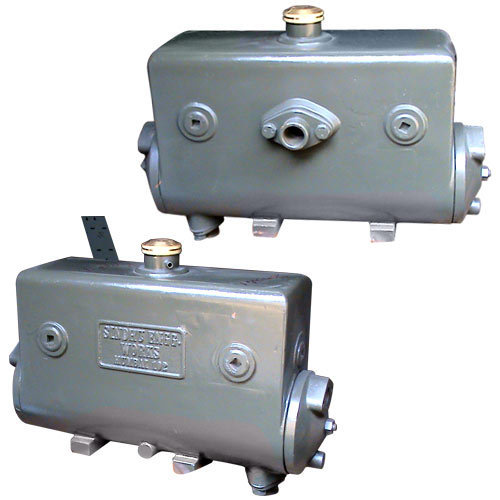

Image:

Specifications:

Copper tube dia 15.88 2), Marine heat exchanger YXH-02-DH, Temperature:-40 ~ +65, Humidity:0 ~ 100%, Water and dust proof, High heat transferring efficiency, Competitive price, Structure: Marine Heat Exchanger

Benefits of Significantly higher heat transfer coefficients than for plain or low finned tubes, Heat exchangers with a more compact and lightweight design, Dramatically reduced fill levels (e.g., refrigerant volumes), Ultimate efficiency with minimal temperature differences Precise thermal design with Thermals .

Advantages : High heating efficiency for oil cooling, Compacted size, Easy installation, Stainless steel 316L or titanium shell & tubes, Various connectors for connection, Low Density and High Strength, Excellent Corrosion Resistance, Good resistance to effect of heat, Excellent Bearing to cryogenic property, Nonmagnetic and Non-toxic, Good thermal properties, Low Modulus of Elasticity.

Applications: A primary advantage of a hairpin or double pipe heat exchanger is that it can be operated in a true counter flow pattern, which is the most efficient flow pattern; It will give the highest overall heat transfer coefficient for the double pipe heat exchanger design.