Closed Circuit Evaporative Cooling Towers

Introduction:

Closed circuit Evaporative cooling towers operate in a manner similar to open cooling towers, except that the heat load to be rejected is transferred from the process fluid (the fluid being cooled) to the ambient air through a heat exchange coil. An evaporative cooler (also swamp cooler, desert cooler and wet air cooler) is a device that cools air through the evaporation of water. Evaporative cooling differs from typical air conditioning systems, which use vapor-compression or absorption refrigeration cycles.

Evaporative Cooling Tower

In Evaporative Cooling Tower a small portion of water is cooled and evaporate into a moving air stream which provides cooling to the rest of that water stream. This evaporating water absorbs heat energy from the remaining water and reduces its temperature.

Specification:

- Residential and industrial evaporative coolers use direct evaporation, and can be described as an enclosed metal or plastic box with vented sides.

Closed Circuit Evaporative Cooling Towers Applications:

- Before the advent of refrigeration, evaporative cooling was used for millennia.

- A vessel could also be placed in a bowl of water, covered with a wet cloth dipping into the water, to keep milk or butter as fresh as possible.

Closed Circuit Evaporative Cooling Towers Advantages:

- Easy installation by bolted assembly.

- Flexibility for any plant location and plot plan arrangement(installation over other units).

Types of Evaporative Cooling Towers:

- Direct Evaporative Cooling Towers

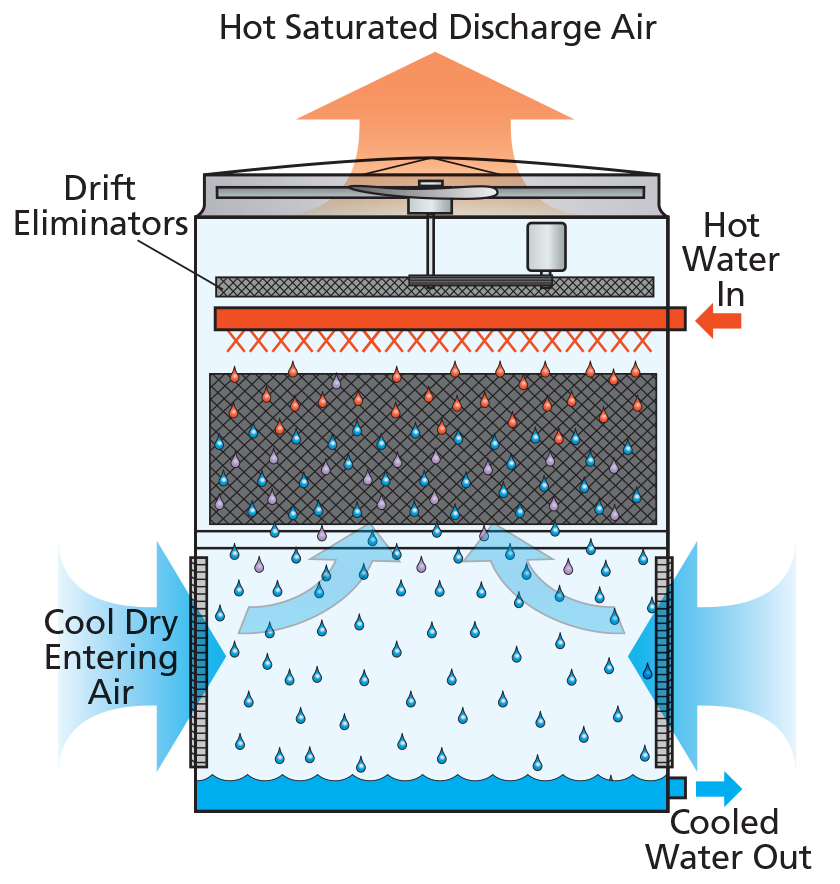

Direct evaporative cooling systems put the process fluid, typically water, into direct contact with air. Water flows through fill as a fan draws air across it, facilitating the transfer of heat from the warm water to the cooler air. This is the system used in open-air cooling towers, such as EVAPCO’s factory assembled cooling towers.

Fig. Direct Evaporative Cooling Towers

2. Indirect Evaporative Cooling Towers

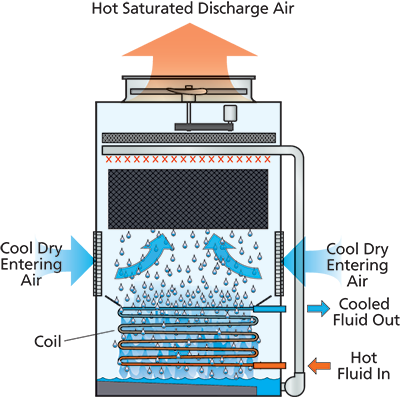

Indirect evaporative cooling systems keep the process fluid out of direct contact with air. Instead, it is pumped through coils, with water flowing across the coils. Water absorbs heat from the process fluid through sensible heat transfer from the coil or piping. This process minimizes the potential for contamination and reduces overall maintenance on the cooling unit. EVAPCO’s closed circuit coolers and evaporative condensers utilize this form of cooling.

Fig. Indirect Evaporative Cooling Towers

Process:

In a closed-circuit evaporative cooler, cooling a process fluid flowing in tubes is achieved by spraying water onto the tubes, deluging them, and forming a film of water that flows downward under the action of gravity. As the water flows down the surface of the tube, it is evaporated by air flowing over it and results in cooling the process fluid.

Images:

Closed Circuit Evaporative cooling towers